Fabric printing

Fabric printing

Couldn't load pickup availability

Transform your creative ideas into stunning textiles with our custom-printed fabric! Whether you're a designer, artist, or hobbyist, our high-quality printing service allows you to bring your unique patterns and illustrations to life on a wide range of fabrics.

Available fabrics:

-

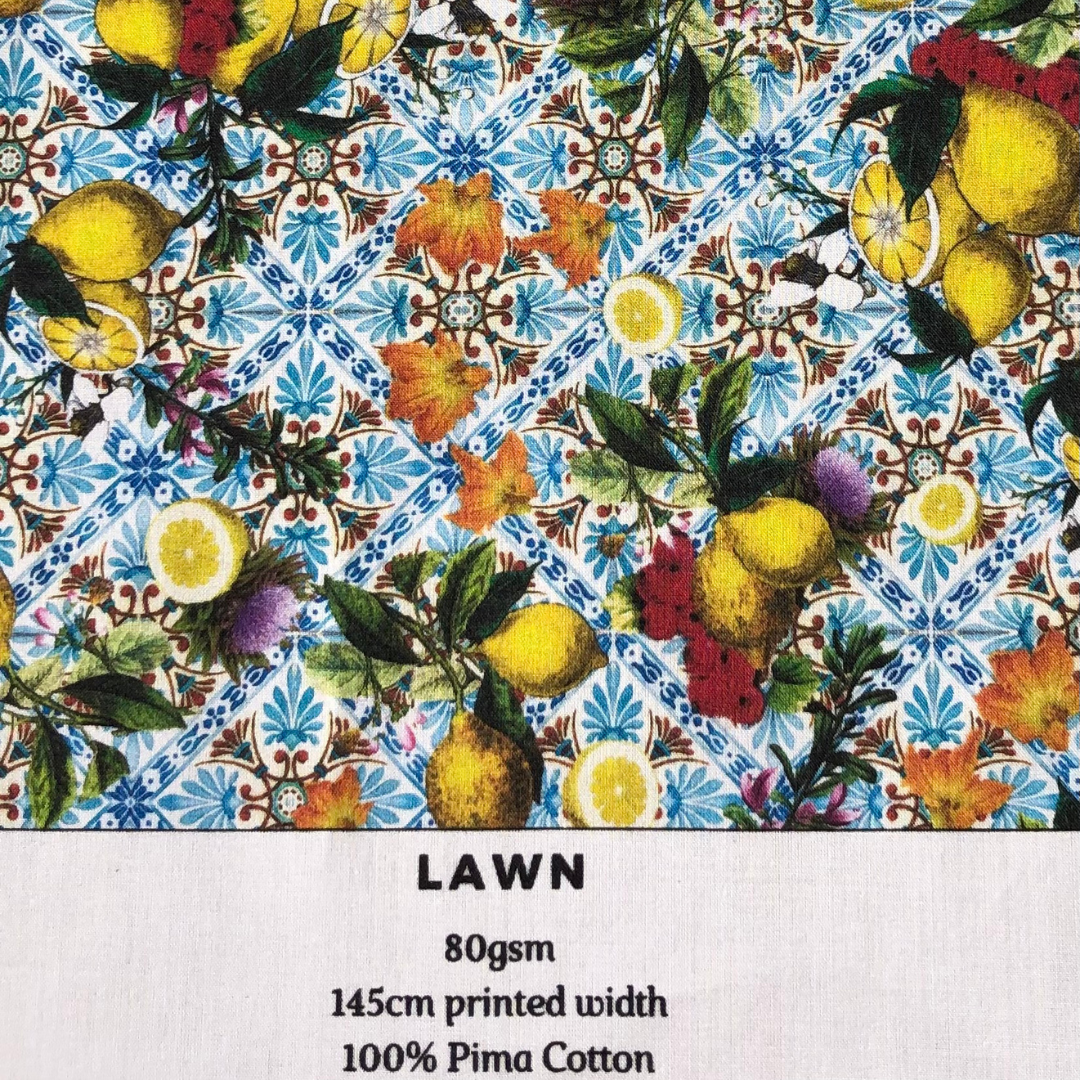

- Lawn 145cm

- Plain Cotton 145cm

- Twill 145cm

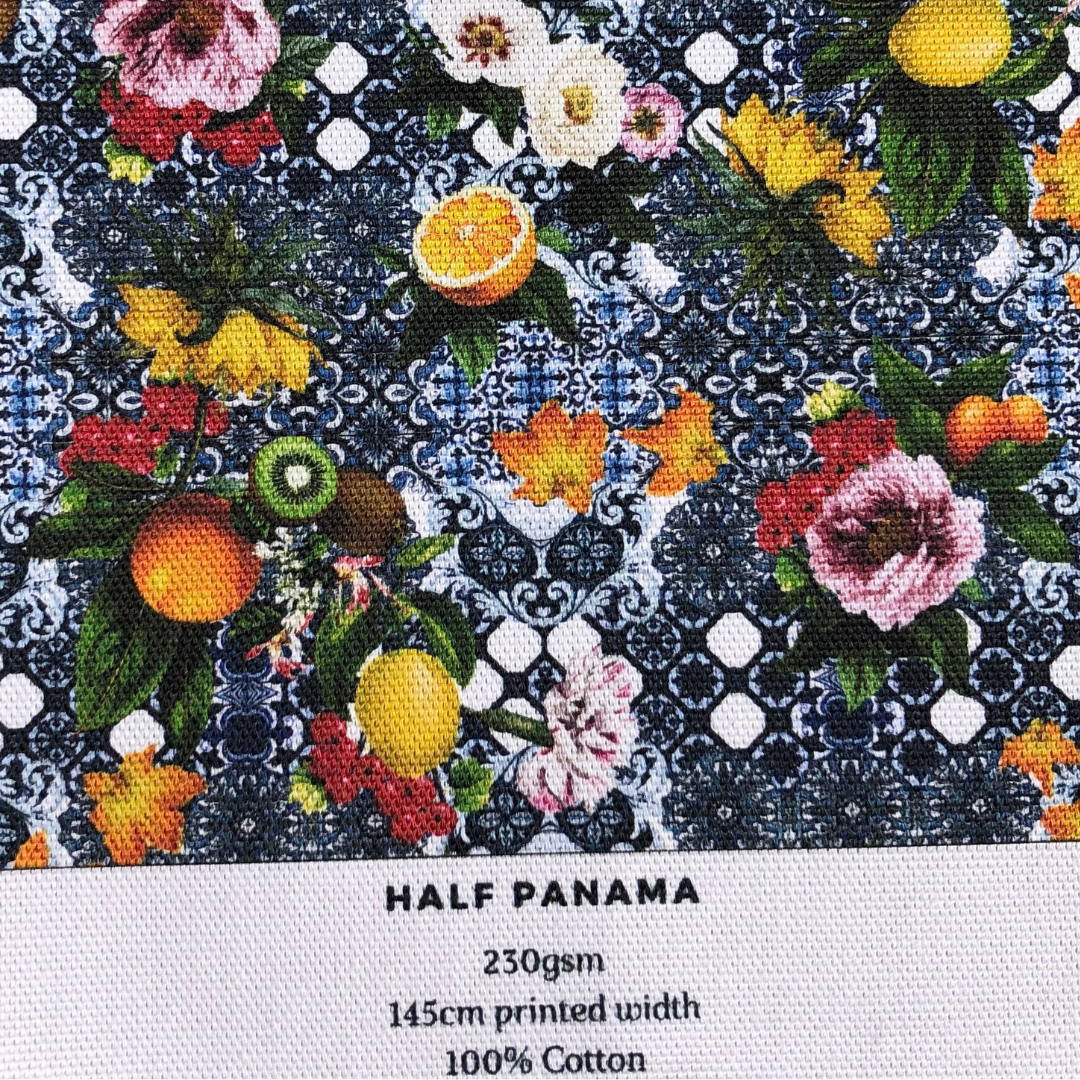

- Half Panama Cotton Canvas 150cm

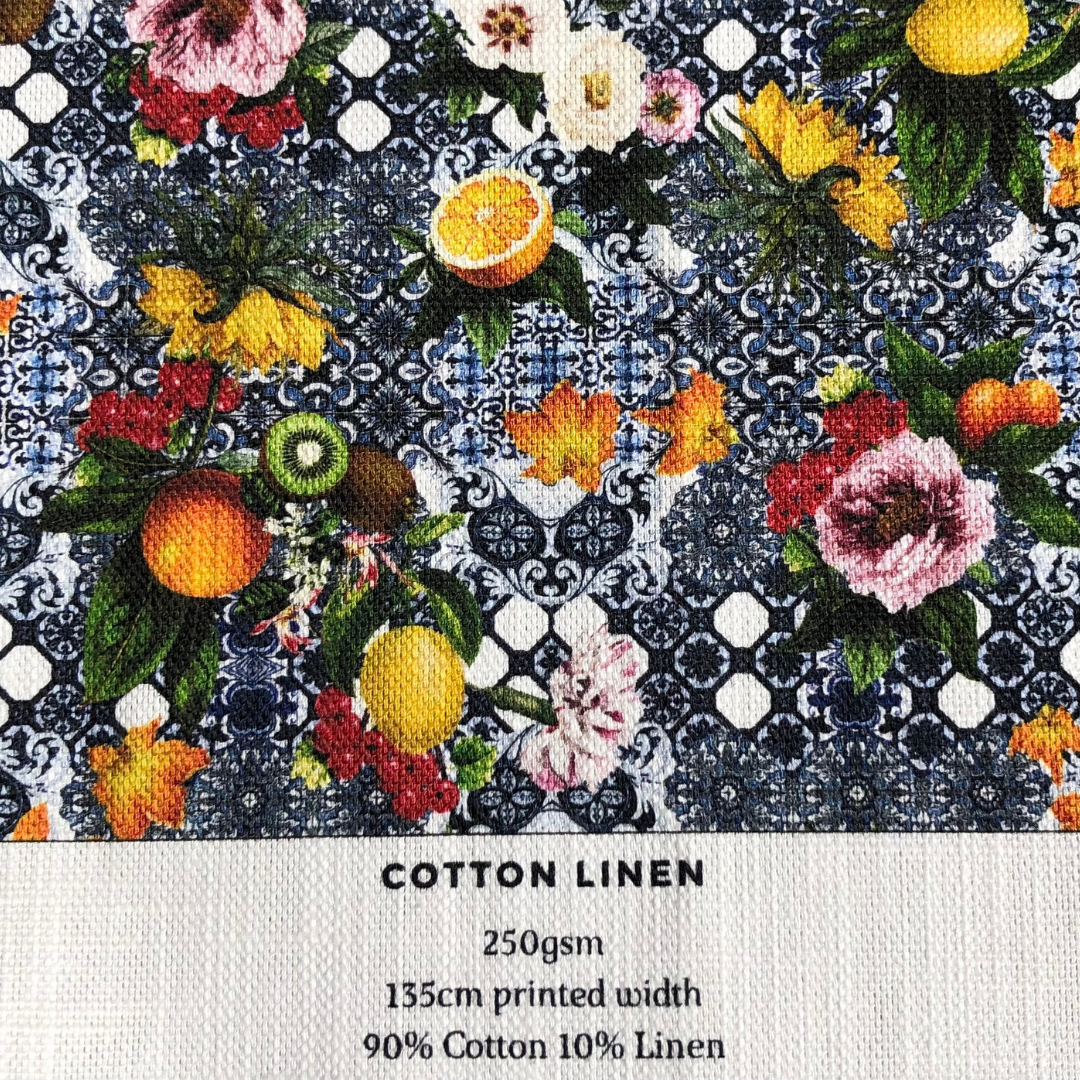

- Cotton / Linen 135cm

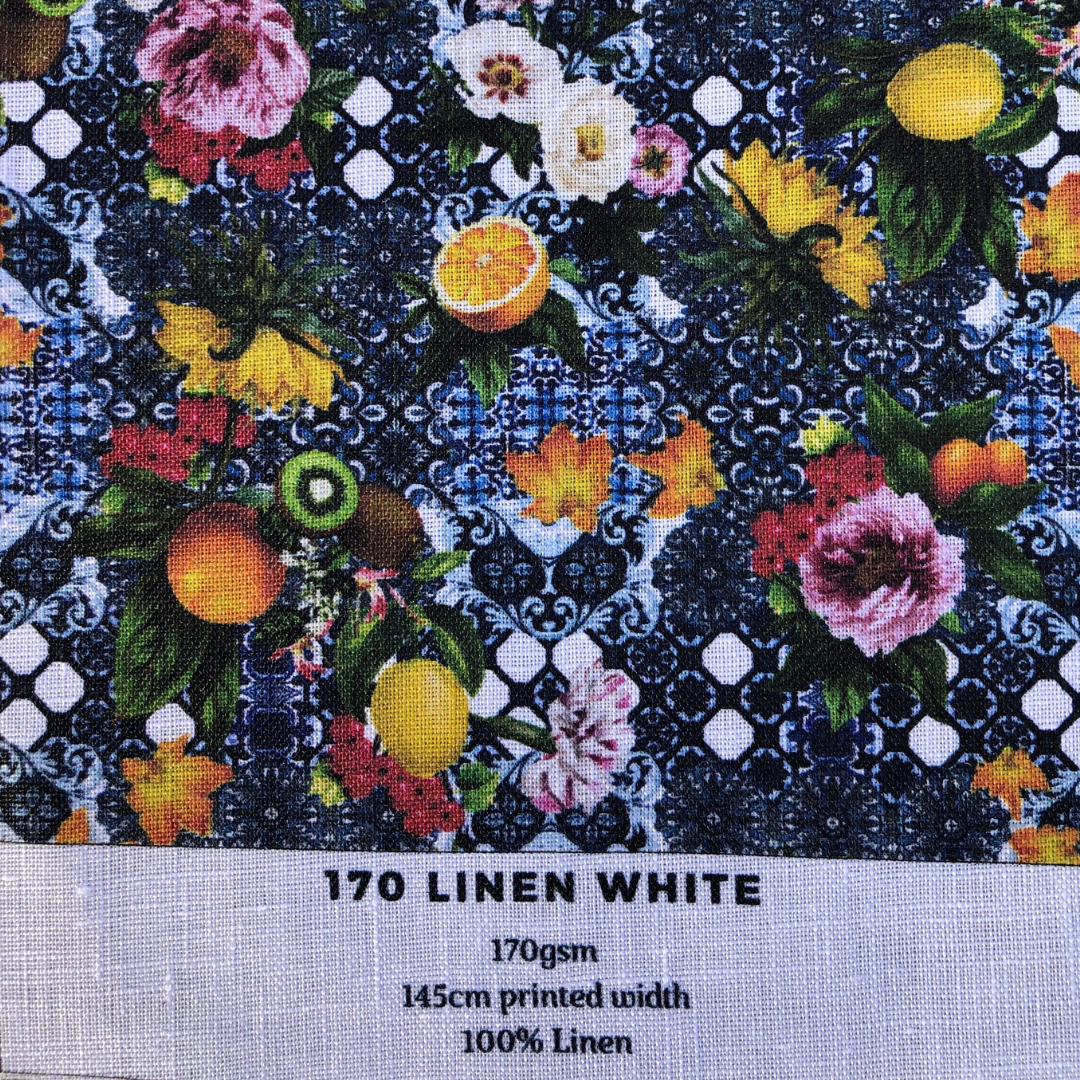

- 100% Linen 170gsm white 145cm

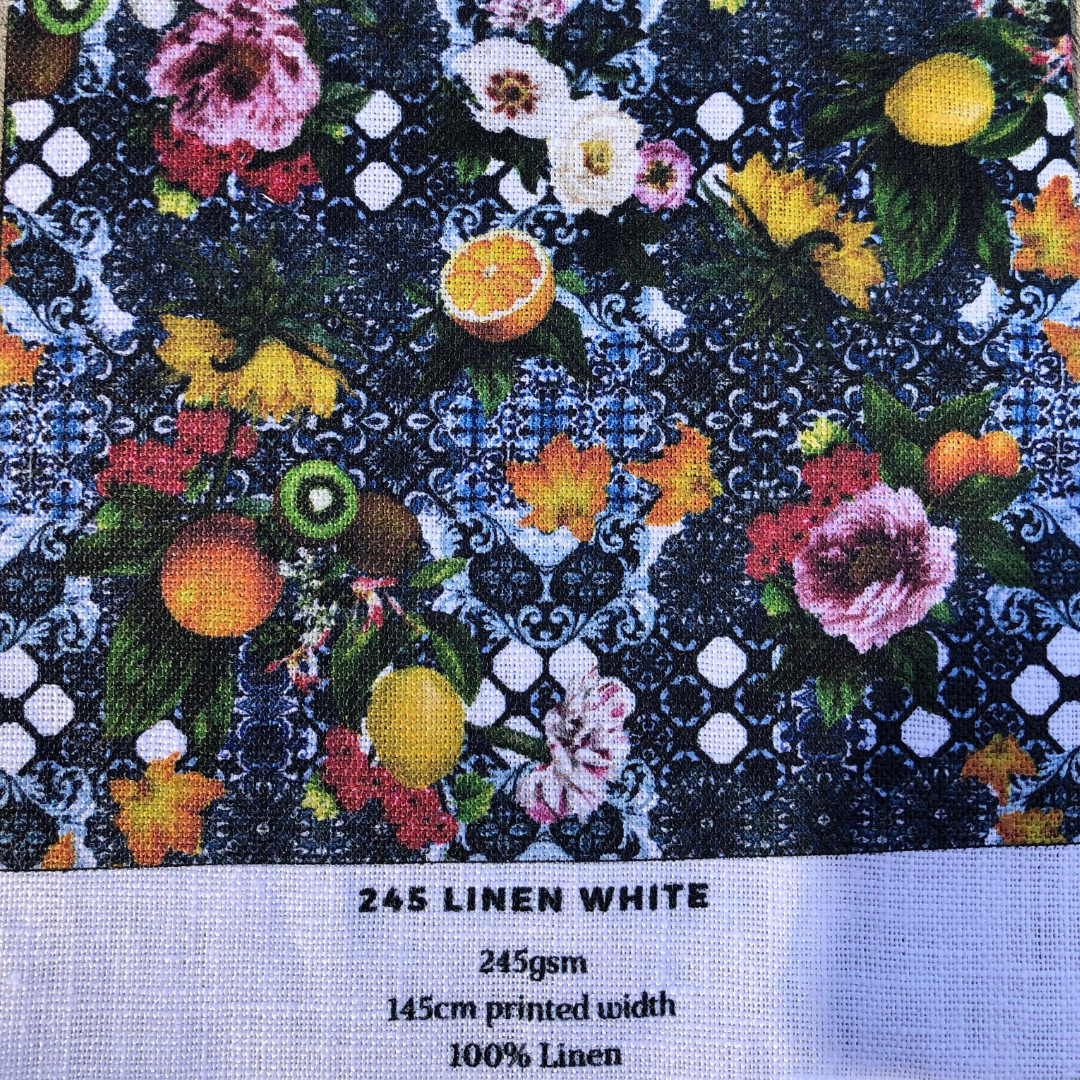

- 100% Linen 245gsm white 145cm

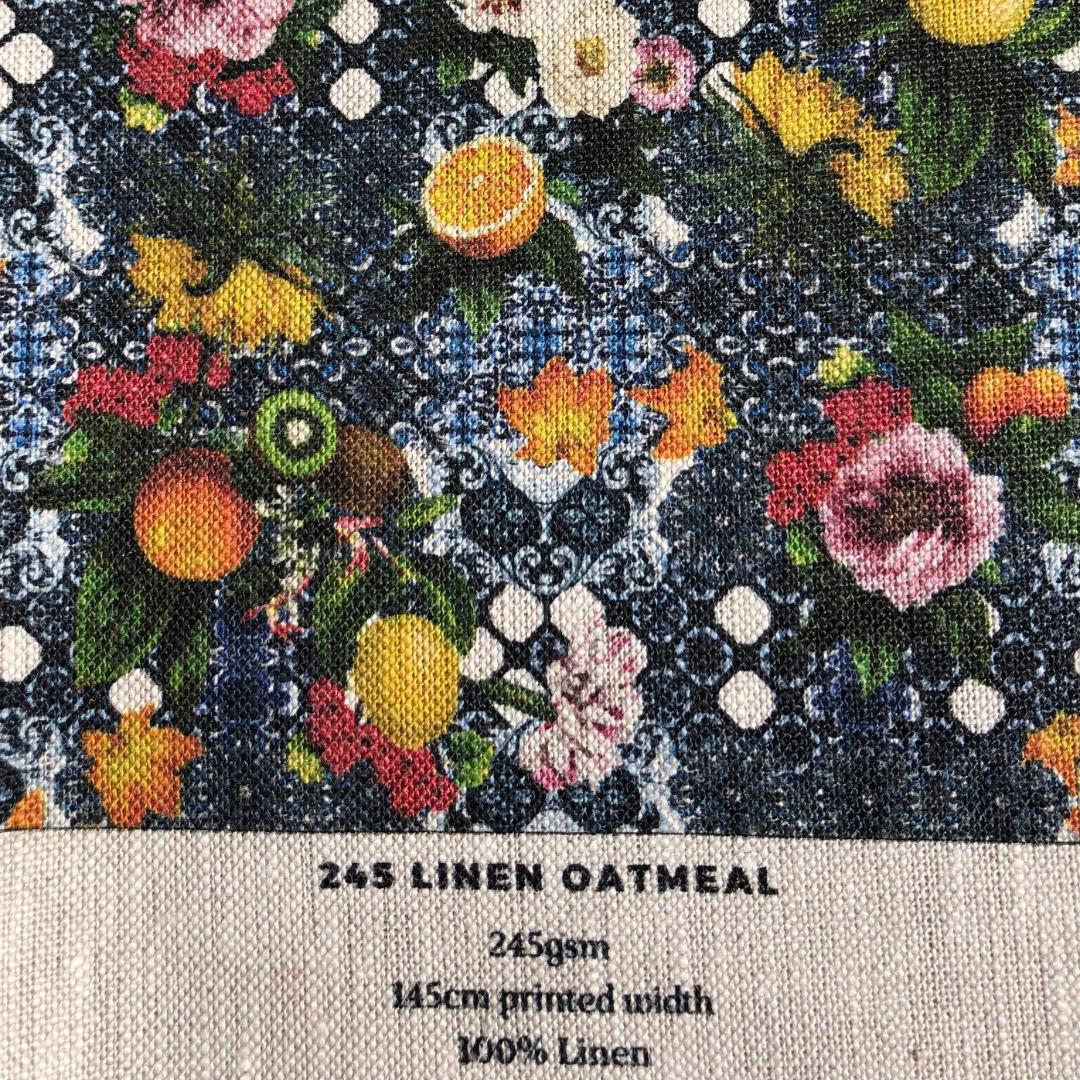

- 100% Linen 245gsm oatmeal 145cm

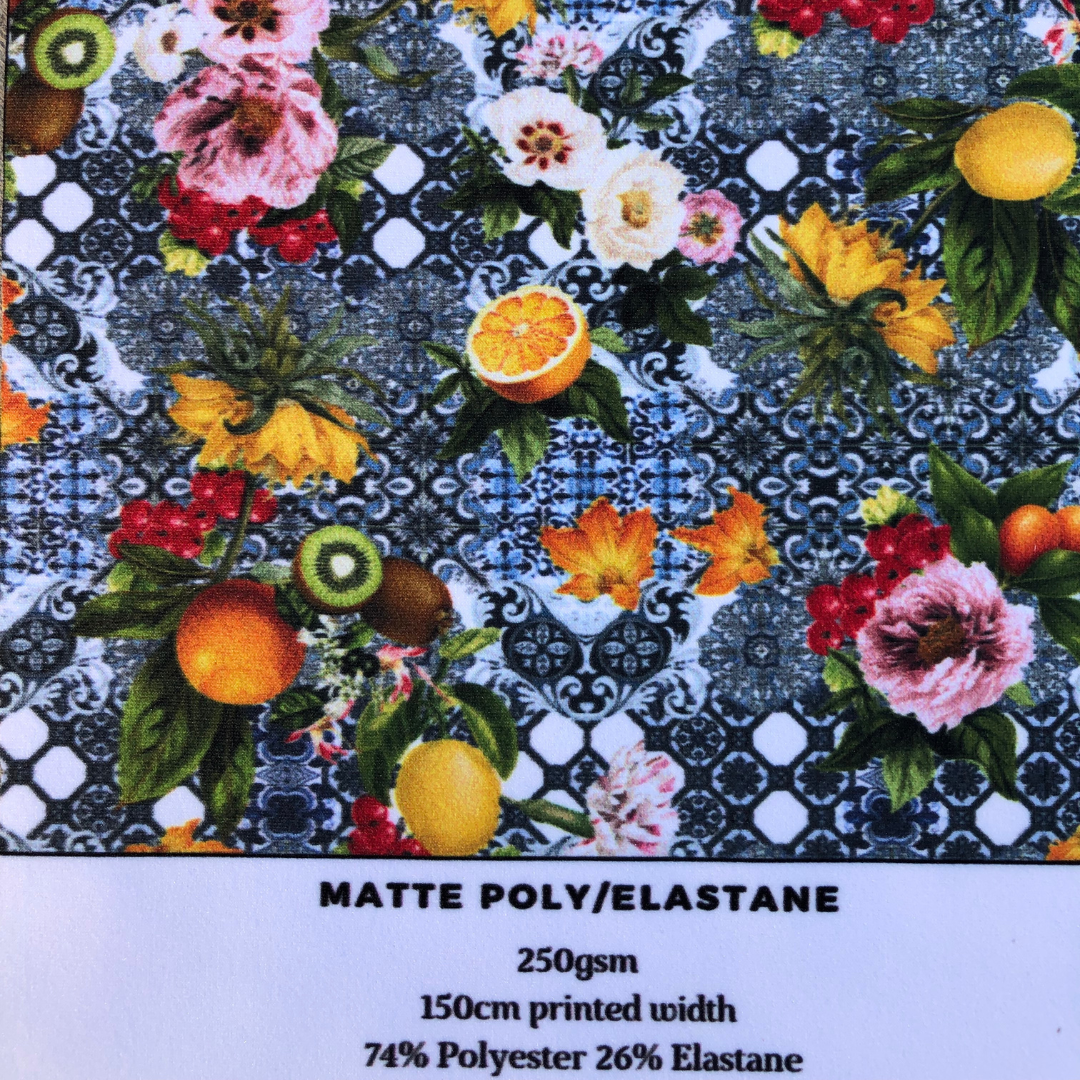

- Matt Polyester/Elastane 145cm

- Shiny Polyester/lycra 145cm

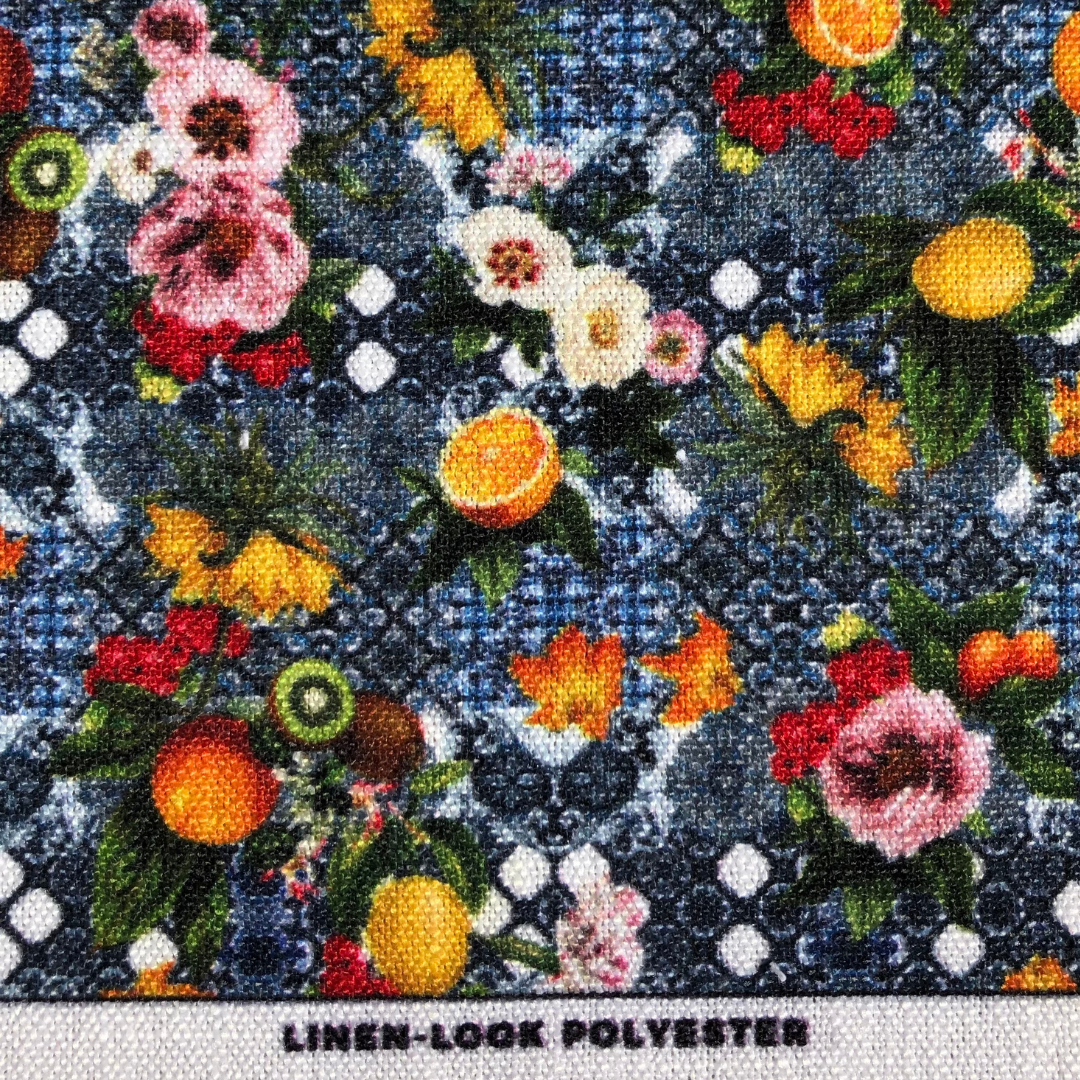

- Linen-Look Polyester 145cm

- Heavy Polyester Canvas 145cm

- Mid-weight Polyester Canvas 145cm

- Polyester Velvet 145cm

- Towelling 145cm

- SCUBA 145cm

- PONTE 145cm

- Peachskin 145cm

-

- Crepe Georgette 145cm

- Satin 145cm

- Silk-look poly 145cm

- Viscose 145cm

Note that we do not use white ink. Any pure white areas of your artwork will be the colour of the base fabric.

Please remember that your artwork will print colours differently on every base fabric. Please consider sampling before going to production especially if you intend to sell your final product.

Bulk order prices

Order over 20m (same fabric) and save 3%.

Order over 100m (same fabric) and save 5%

Discount is applied automatically at the checkout.

How long will it take?

How long will it take?

Production will commence upon payment. Our standard turnaround time is approximately 7 - 10 buisness days.

Minimum order quantity

Minimum order quantity

Minimum order is 2m (increments of 0.5m)

Digital file requirements

Digital file requirements

File Types

Please send your artwork files as JPG, PDF or TIFF formats.

File Size

If you are uploading via the website, no larger than 5MB. You can retain quality with a smaller file size. Ask your designer how.

Colour Profile

It is preferable that your files are CMYK but RGB is also acceptable.

Note that we do not use white ink. Any pure white areas of your artwork will be the colour of the base fabric.

Please remember that your artwork will print colours differently on every base fabric. Please consider sampling before going to production especially if you intend to sell your final product.

Resolution

Between 150dpi and 300dpi. Please be aware that increasing files to a larger scale can distort the artwork and have a less than desirable print quality.

Scale

If you need to check to see if your artwork will be scaled correctly, please contact us to check the scale and we help you.

Seamless patterns

When your print is repeated with no visible edges, this is seamless printing. If your artwork doesn’t repeat seamlessly, it creates visible areas where patterns do not match up or are incomplete.

We only require one seamless repeatable tile from you, we will create the length and width of the print using that tile.

How to check for design flaws

How to check for design flaws

Occasionally we get designs with flaws. These flaws can be lines, outlines of objects, outline of the tile, repeat match up errors and elements that should have been removed or layers that should have been hidden. These errors may not be visible on a test swatch. For example, if your repeat size is 25cm x 25cm, an 20cm x 20cm test swatch won’t show the edges of your repeat.

To ensure those who order your designs don’t get a flawed print, it’s best to check for mismatched repeats or lines in the design. These lines can be blank, white, or a different shade of the background colour breaking the repeat of your design. Typically it happens along the edges of the design, making it harder to find. You are responsible for providing print ready artwork. Please double check your artwork and send it to your designer if you find any flaws.

Shrinkage

Shrinkage

When working with fabric it is important to remember that natural fibres are expected to shrink when initially washed and care needs to be taken during subsequent washes to avoid further shrinkage. Shrinkage occurs on the warp and the weft of the fabric (that is to say, both directions of the fabric).

Shrinkage of 6% to 7% is to be expected and allowed for when ordering fabric.

The charm of natural fibres

The charm of natural fibres

Due to the nature of natural fibres, your fabric may have slight imperfections such as knots or slubs, these are all part of the charm of natural textiles and not an imperfection in the printing process.

On occasion, dirt marks and small holes are present within

the role of fabric and are a result of the milling process.

Care instructions

Care instructions

Your natural fibre fabrics should be hand-washed in cold water, or washed on the most gentle cold cycle of your machine with a low spin, dried inside out in the shade, they should not be bleached, wrung, rubbed or tumble dried. Iron on the reverse side. Phosphate free washing detergent is advisable.

Our Polyester fabrics can be washed in warm water, they should not be bleached, wrung, rubbed or tumble dried. Do not iron. Phosphate free washing detergent is advisable.

Shipping

Shipping

All fabric orders over 10m will be shipped on a roll via courier unless otherwise requested. In this case, an additional handling fee will be charged.

All print-on-demand fabric and custom-made products will be shipped via courier unless Australia Post is requested.

All velvet orders will be shipped on a roll via courier.

Orders requiring international shipping will be provided with a quote for you to approve.

Return policy

Return policy

Print-on-demand fabric and custom-made products cannot be returned for a change of mind. If there are faults in your fabric or products please contact us directly.

Due to the nature of natural fibres, your fabric may have slight imperfections such as knots or slubs, these are not an imperfection in the printing process. On occasion, dirt marks and small holes are present within the role of fabric and are a result of the milling process.

Various, unavoidable circumstances may cause slight imperfections in the print job when printing on a natural fibre. Faults totalling 3% of the print job are considered acceptable and not grounds for re-printing at the printer’s expense. Please discuss major printing faults that deem the fabric un-usable with us directly. If it is agreed that APPLiK will re-print the job at their expense, the faulty print job must be entirely returned before re-printing.

We highly recommend

-

Test print sample

Regular price $22.00 AUDRegular priceUnit price per -

Fabric sample box

Regular price $22.00 AUDRegular priceUnit price per -

Colour charts

Regular price $55.00 AUDRegular priceUnit price per

How it's made

The great thing about being a print on demand service is that so little waste is produced. We only print what is needed. Using a digital printing method with pigment inks means that no water is used during the printing process like some other methods of digital printing.

Direct to fabric digital pigment printing

Using a digital printing method with pigment inks means that no water is used during the printing process like some other methods of digital printing.

The fabrics used here at APPLiK are sourced from specific suppliers who specialise in fabrics that are prepared specifically to be printed on with pigment inks. After your design is printed onto the fabric of your choice it is passed through a heat press where is cured ensuring that the print is colour-fast.

Dye sublimation

In order to print onto polyester base fabrics, a different method of printing is used called, dye sublimation. The print for your polyester base fabric is printed onto heat transfer paper then transferred to the base fabric via a gassing off process when it is heated in the heat press.